Articles / Advice

Airless Spray Tips Made Simple - A Step-by-Step Guide to Choose the Right Tip

We all want that pro-level finish every time, but that’s not always the case. The reality of swapping between materials and substrates is that when it comes to airless spray tips, one size does NOT fit all.

So, when do you use what spray tip?

What’s the deal with FFLP and LP tips, they’re both low pressure but what’s best for what application? LTX vs. RAC5? 312 vs. 514? WideRAC – is that even a thing?

It seems that Graco spray tips sometimes read more like a foreign language than anything else. The goal here, then, is to shed some light on the situation and hopefully – hopefully – bring some method to the madness.

Like, did you know you may be spending hundreds of extra dollars unnecessarily? Spray tip secrets coming your way…

Skip ahead?

Graco Airless Spray Tip Range Explained

Before choosing a size, let’s talk about Graco airless sprayer tip types. There are 7 key tips in range, each distinguished by code and colour.

LTX Spray Tips – Blue

Jack of all trades, master of none

Guard: RAC X

Orifice sizes: 0.007” - 0.071”

Ideal applications: Most airless sprayer applications

LTX tips are essentially Graco’s ‘general’ range of spray tips. With their massive range of fan widths and orifice sizes, they can be used for almost all airless spray applications. In this way, if in doubt an LTX spray tip will probably work.

The other key benefit of LTX’s is their price – they are cheaper. Now I’m not talking $20 cheap, they are still a high quality product, but they're cheaper than your FFLP’s or XHD’s. And, if you’re a house painter, you might even find they last longer too – but this is very application specific.

The benefits of their generalist nature do come at the cost of specialty though. These tips won’t achieve the same quality of finish as a fine-finish spray tip and they’ll have to operate at a higher pressure in order to atomise your material, meaning more wear on your sprayer.

Does this make them a bad spray tip? No, of course not. Just because I wouldn’t use my mobile phone as a hammer doesn’t make it a bad phone. It’s just a matter of application.

When to use an LTX spray tip?

LTX tips come in handy for film build - if you’re spraying a substrate that requires a thick coat, LTX tips often get the job done perfectly. This is why they are very common for roof re-paints and restorations. The cost factor comes in here too since these materials are usually more abrasive and harder on your spray tips – as they say, cash is king.

The finish quality is still decent, however not in comparison to the Low Pressure (green) tip range, they’re next level.

Some trades do prefer the way the LTX tips atomise since the gradient is not as significant and provides a ‘sharper edge.’ Thus they can being quite popular for guttering, exterior trim work, and a mix of commercial and industrial applications.

RAC5 Spray Tips – Black

Jack of all trades but master of none… RAC5 though

Guard: RAC 5

Orifice sizes: 0.007” - 0.065”

Ideal applications: Line marking stencils, DIY ‘standards’

Take all the benefits and limitations of the LTX spray tips, put them in a RAC5 tip guard and you’ve got Graco’s RAC5 spray tips.

Honestly, it’s true. Just dial it up things a little more: take the price factor down even further and the spray finish also takes another hit.

We would not recommend RAC5 spray tips for residential painting, and nor does Graco. These tips do not come standard with any of the professional airless range of sprayers, they all have RAC X guards. They were, however, previously included in Graco’s DIY Magnum range of airless sprayers. They have since been superseded by the TruAirless range though – so good news for you pro DIYers.

Why have both RAC5 and LTX tips in the range?

RAC X and RAC 5 guards can usually be split in their application purpose. Let me explain with an example:

Line marking tips (LL5) use a RAC5 tip guard, so when you need to swap over from line striping to a stencil it’s an easy swap to a RAC5 tip without the need to change the tip guard. Compound this ease with a team of four line markers, and the ‘keep-it-simple’ principle is pure gold.

Likewise, a house painter would predominantly use RACX tips – FFLP, LP, LTX & WideRAC – so if they want to spray a ceiling flat after trim, no tip guard swap required. Super easy.

What we don’t fully understand, is why the DIY Magnum range uses a RAC V guard. Though more expensive, the FFLP tips are what we recommend for DIYers and most residential applications. Their combination of lower operating pressure and finish quality makes them super forgiving and the ideal DIY choice. What we put it down to is segmentation, keeping the contractor/industrial range separate from homeowners. Nothing too significant, it just is what it is.

When to use an RAC5 spray tip?

To keep it simple, if you don’t have to use RAC5 tips… don’t.

They are a previous generation to the RAC X LTX/LP series of tips, so for decorative finishes use that RACX range when possible. You will simply get more out of your airless spraying equipment if you head that route.

Where the RAC5 tips have a sweet spot is in line marking and striping. As mentioned, the RAC5 and LL5 tips share the same tip guard, so when swapping between it is simply easier.

Honourable mention: TruAirless - Black

The latest DIY, Magnum range.

Guard: RAC V

Orifice sizes: 0.008” - 0.016”

Ideal applications: House painters, fine finish work, latex paints, trim, etc.

Harnessing the contractor range technology in a DIY spray tip is a definite win. The major limitation is very clear and simple though, they don’t sell these tips independently in Australia (as at 2022 anyway).

So, you’ll get a TruAirless 515 spray tip with your new Magnum airless paint sprayer, but you’ll need to opt for alternative tips if you want to use different sizes after that.

What we recommend is the investment in a RAC X guard and FFLP spray tips for DIYers. The FFLP combination of finish quality and lower operating pressure provide a forgiving spray experience for those getting into the space, and all without compromising spray finish.

It’s also handy – particularly for those who are not 6’6” - to get a tip extension to enable ease of reach for upper walls, etc. In fact, we’ve put together all our recommended spray accessories into the ‘GO Spray More Kit’. It includes: 2 x FFLP, RACX guards, 40cm tip extension and a 950ml pump armour. The DIYer dream, bundled and discounted. Note, it may already be included in some of the Magnum sprayers.

Fine Finish Low Pressure (FFLP) Spray Tips - Green

Our most popular spray tip – premium finish at half the pressure

Guard: RAC X

Orifice sizes: 0.008” - 0.016”

Ideal applications: House painters, fine finish work, latex paints, trim, etc.

These are our most popular spray tips and for good reason. They feature an enviable combination of a great finish and cost-effectiveness.

“Cost effectiveness? Aren’t they more expensive than the LTX’s and RAC5’s?”

Yes, yes they are. BUT their low pressure benefits maximise their value. Let me explain.

What’s the benefit of low pressure spray tips?

Let’s jump straight to the punchline, low pressure spray tips operate at up to 50% that of an LTX or other brands standard tips. This means 3 significant benefits:

- Reduces overspray

- Doubles the lifetime of your spray tip

- Extends the life of your pump / pump packings

Some quick math will tell you that between the spray tip and pump life extension, you’ve more than covered whatever extra money you initially spend on the tip.

As a general rule, you should desire to operate at the lowest possible spray pressure that still perfectly atomises your paint and any low pressure spray tip is therefore an ideal choice.

When to use an FFLP spray tip?

When you’re thinking FFLP’s, you’re thinking decorative and everything else in between. Their ability to beautifully atomise material, provides a very desirable gradient and finish.

For example, the FFLP516 is a sweet-spot for spraying undercoat over bare plaster, and the FFLP310 for water-based enamel on doors, frames and window trim.

There’s a variety of sizes to suit interior and exterior spraying, and will keep that overspray to a minimum whilst maximising your finish quality.

The FFLP’s are not the ideal choice when it comes to more abrasive/hardy materials, like ceiling flats or large volumes of exterior acrylics. The double mesh/atomising feature that produces the enviable finish, provides double the mesh to wear through too. Will they still spray these materials? Absolutely, they will wear the FFLP tips faster, so perhaps the LP series of tips are a better fit for these applications.

Low Pressure (LP) Spray Tips - Green

Low pressure for high production

Orifice sizes: 0.013” - 0.031”

Ideal applications: Ceiling flats, exteriors, undercoats

What’s the difference between Graco FFLP and LP spray tips?

The major difference between the FFLP v. LP is the FFLP has a double-atomisation design. This builds in two layers of ‘mesh’ for the paint to pass through, providing that superior finish, reduced overspray and ease of blending. Consequently, though, this also builds in two layers for paint to wear.

Enter low pressure, LP, tips. Without the dual mesh design, they have a longer life than that of the FFLP - still superior to LTX’s though - but with the compromise of a ‘less’ fine finish.

Where this comes in handy is for higher production more abrasive materials. Think undercoat, ceiling flat, exterior paints. These sorts of materials would wear an FFLP tip quite quickly, so by using an LP you get all the benefits of a low pressure design but has a longer life.

An additional, though strange, difference between the FFLP and LP, is that FFLP’s only come in even orifice sizes and the LP’s in odd. We honestly don’t know why, it’s just a quirk, which keeps things fun and exciting…

When to use an FFLP and when to use an LP spray tip?

Rule of thumb - any larger surface areas, bigger spay-days and projects, you’ll want to lean towards the LP tip range. The same goes for more abrasives paints - ceiling flats, undercoats, satin/flat/low-sheen products. We’ve had a tonne of feedback and experience that the LP tips ‘blow’ a little bit more than the FFLP range, so be mindful of slightly increased overspray when tackling these projects.

So, when do we use the FFLP tips?

For anything, and everything in between! We often recommend our FFLP tips for finish-coats on walls, narrower equivalents for woodwork, trim, and any decorative spraying. The double-orifice and atomisation out of these tips are simply beautiful, and should be put to work whenever possible. For example, a bit of a hack for us, is using a combination of FFLP414/FFLP514 tips for the final coat on walls in a low-sheen acrylic paint. This provides a fantastic, even coat to be marvelled.

WideRAC (WR) Spray Tips - Blue

Spray lots fast

Guard: RAC X

Orifice sizes: WR1221 - WR1239

Ideal applications: Roof painting, commercial and industrial surfaces

WideRAC rightly live up to their name. Where your LTX tips go up to a 14” fan, your WR tips are fixed at a 24” fan.

They are specialised for high production industrial applications – roofing, warehousing, large runs of wall, etc. – and have a limited range of orifice sizes to suit. You won’t be spraying interior paints, this is made for membranes and high viscous materials.

“Spray lots fast,” sounds dumb, but that’s exactly where these WideRac tips slide into the range. Notes, for applications where overspray is NOT an issue.=

We don’t see a massive quantity of these go out, but they are super handy for their speciality.

XHD (XHD) Spray Tips - Grey

Hard-to-spray industrial coating specialist

Guard: XHD

Orifice sizes: 0.0107” - 0.0481”

Ideal applications: Industrial and commercial protective coatings

The XHD range is its own family of equipment. XHD spray tips are used exclusively with XHD guards in XTR spray guns for extra tough, highly abrasive commercial and industrial protective coatings.

Typical applications would be bridges, petroleum tanks, farms, structural steel and roofing.

These are for highly abrasive materials that typically require an air-driven airless spray configuration. You’re talking Merkur airless sprayers setups.

Line Lazer (LL5) Spray Tips - Yellow

Line marking specialist

Orifice sizes: 0.013” - 0.055”

Ideal applications: Line marking / striping

LL5 tips are built specifically for line marking / line striping. There are two factors worth noting here: spray pattern and build.

Where residential and commercial painters require the edge of their spray pattern to be a nice gradient so they can blend passes, line markers need a single pass with a hard edge. That is what these tips are engineered to do.

Then, road paint is abrasive and viscous, therefore you need a tip built to endure that sort of punishment.

Tips and other tricks

What does Graco ‘RAC’ spray tips mean?

The "RAC” in Graco RAC tips and guards, simply refers to ‘Reverse-A-Clean’.

This is Graco’s tip blockage removal system, where a simple rotation of the spray tip enables you to remove the blockage. One direction is spray and the other is a stream.

Are airless spray tips universal? Can I use Graco spray tips with a Wagner or Titan?

Yes, Graco spray tips can be used with other sprayers BUT only with a Graco tip guard. Graco, Wagner, Titan and a bunch of other sprayer manufacturers use 7/8" thread on their spray guns, and therefore can share sprayer accessories between them.

So as long as you have 7/8" thread, you’re good to spray!

3 key steps to choosing the right tip:

- Choose the right size for the right paint

- Filters - don’t stop the flow

- Is your sprayer compatible?

1. Choose the right spray tip size for your paint

On the most basic level, you need to have a tip with an orifice size rated for the paint or coating you’ll be spraying.

Light coatings such as lacquers, stains, and enamels require a small tip, while heavier coatings such as membranes and textures require larger spray tips.

What do the numbers on an airless sprayer tip mean?

Those three digits you see on airless sprayer tips, indicate two things: the spray tip fan width and the spray tip orifice size. It’s the combination of these two numbers that give you your spray tip size.

For example, let’s take a FFLP312 spray tip.

The first number, when multiplied by 2, indicates the size of the fan the tip will create when sprayed at a distance of 12 inches (30cm) from the surface – a 312 creates a 6-inch fan.

The remaining two numbers indicate how much fluid will leave the spray tip via a measure of orifice size, in thousandths of an inch – 312 has a 0.012-inch orifice.

Paints that have a lower viscosity (aka. “thinner” paints), will require a smaller orifice in comparison with more viscous paints that will require a larger orifice to atomise the paint.

If you have a thin material being sprayed through a large orifice, the spray tip will flood the surface resulting with runs and drips.

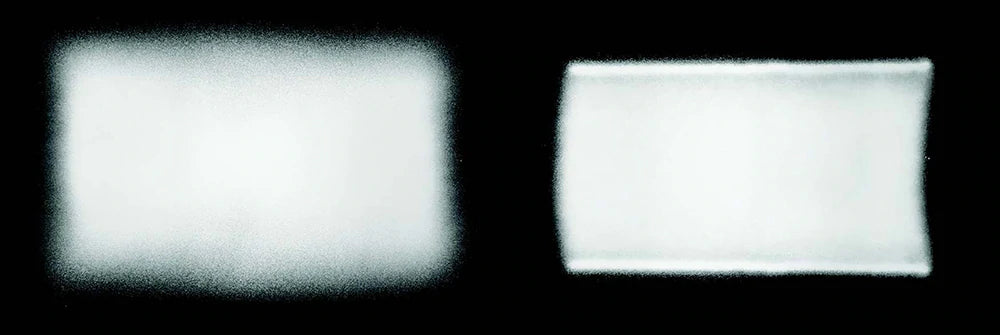

If your material is too viscous for the orifice, the fan will produce undesired tails (see image below), or may constantly block due to flow restriction, or even not spray at all.

Left: Quality Finish. Right: Finish with Tails

This is why you should check the specs sheet for the material you’re using. Many paint manufacturers will specify recommended spray tip sizes on the tin or product TDS (specification sheet).

Tip Guide: Recommended tips sizes for common applications

|

2. Filtration - keep the flow

Not necessarily a tip choosing aspect, but your filters matter.

Filter size, material viscosity and flow rate all have an intimate relationship.

If you're spraying a thicker material, it will require a larger mesh otherwise the flow rate of your sprayer will be hindered, the paint won't atomise and you'll be revisiting the tails image above.

From Graco's two filter sizes, distinguished by colour: 60 micron (black) and 100 micron (blue), here's your cheat sheet:

Any material exceeding the viscosity of a 0.017” orifice, requires a black (60 mesh) filter. For 0.017 and thinner, a blue (100 mesh) is recommended.

Great. Step 2, done.

3. Is your paint sprayer compatible?

This is a quick one. Simply, make sure that your sprayer can handle the spray tip size your material needs.

Thicker materials require larger orifice sizes.

Larger orifice sizes require more power.

Just look up the ‘max tip size’ specification for your sprayer and ensure it’s compatible with your desired material.

Additionally, if you plan on running two spray guns from a single machine – Graco 650 upwards – you’ll need to check the max tip size when dual wielding.

There you have it, you are now a spray tip aficionado – able to wield the Graco spray tip like a pro.

If all else has failed you, feel free to get in touch with the team here. We’ll give you a hand in spec-ing out your gear.

Tip Wear – the secret money drain

Want to save yourself hundreds of dollars a day?

Replace your tips regularly.

This may not seem like a key consideration, but like everything else that you work with, spray tips wear. And it can have a major cost.

Below you can see examples of four fans at differing levels of wear. You’ll notice that as a spray tip wears, the fan reduces but it continues to spray the same quantity material. If your 6-inch fan reduces by half, it means that you are doubling the number of passes and in turn doubling the quantity of material used.

Essentially, less of a fan-width means more passes. More passes mean time and material. More time and material mean more cost.

I’m not sure what you’re paying for material and labour, but I imagine that you’d prefer to invest $60-$90 more frequently than the hundreds of dollars on unnecessary expenses that take away from your bottom line.

So, keep this in mind when buying your tips.

4 Essential Spray Tips Every Painter Needs

After all of that, filled up with the knowlege tip types and sizes, here are our FOUR ESSENTIAL spray tips we think every painter should have.

This is great is you’re just starting out, a pro DIYer tackling larger projects, or just want to make sure you’ve got something in the arsenal that will get you out of a tight spot.

Here they are:

These are tried and tested by our VIP contractors and have proved themself over and again.

As we suggested in out type breakdown, FFLP and LP are our top picks. FFLP for everything decorative and finishing, and LP for production/abraisve applications.

If you have these four spray tips in your tip saver storage, you won’t be sorry.

Conclusion

There you are! Types, sizes, choosing and essentials all in one place.

Make sure you share this with your fellow painters, apprentices and anyone who needs a degree in Graco gear. Check

If you’ve got questions or are unsure which tip is best for you, get in touch with our experienced team! We will do our absolute best to find the best suitable tip for your application.

Happy spraying,

The GO Team.

See our range: Graco Airless Spray Tips

Other helpful Articles

- Choosing a selection results in a full page refresh.

- Opens in a new window.

![Minimalistic Coastal Scandi Reno - Top Questions Every DIY Painter Wants to Know When Starting to Spray [Q&A] - GO Industrial](http://goind.com.au/cdn/shop/articles/minimalistic-coastal-scandi-reno-top-questions-every-diy-painter-wants-to-know-when-starting-to-spray-qa-420101.jpg?v=1739931521&width=533)