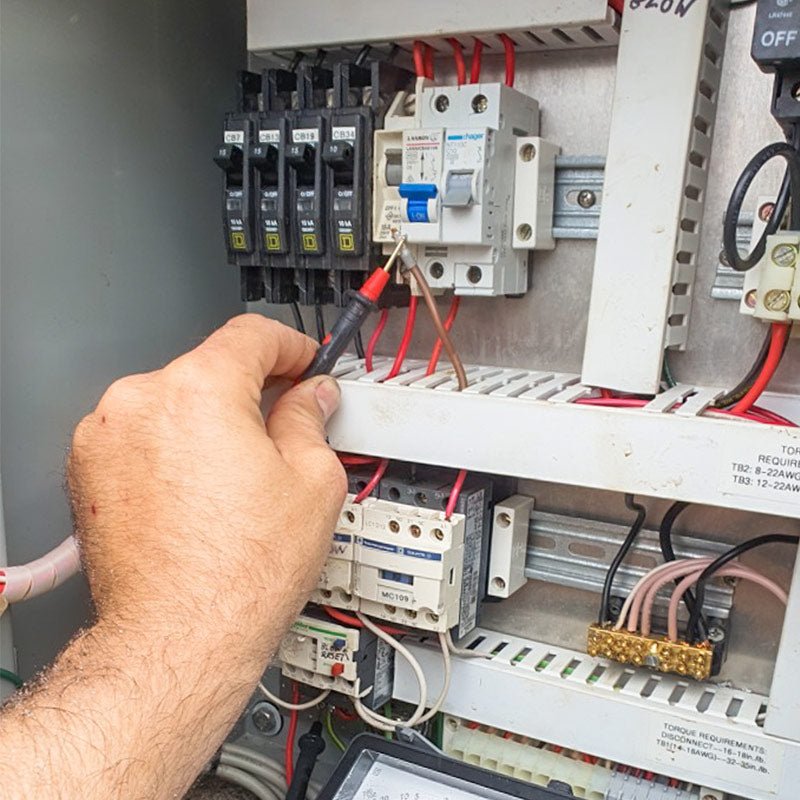

Fuel Facility Maintenance and Repair

Fuel Facility Maintenance and Repair

Overview

Your bulk fuel facility is often an overlooked aspect of your operation. We get it, each and every day you are flat out focussing on your core business.

What is the cost of your business of a safety incident, fuel spill, facility breakdown or inaccurate accounting of your fuel consumption?

The risks of not maintaining your fuel facility are high!

So, let the GO Team take on the time and stress of the maintenance management of your fuel facility. Our core is your non-core. We are focused on fuel equipment.

Recently Viewed Products

- Choosing a selection results in a full page refresh.

- Opens in a new window.