Enquire For Price

Delivery & Shipping

GO Ball Check Valves Back Flow Prevention Ductile Iron BCV

Regular price

From $143.00 AUD

Sale price

From $143.00 AUD

Regular price

Unit price

per

Save $0

Sold out

GO Ball Check Valves Back Flow Prevention Ductile Iron BCV

Overview

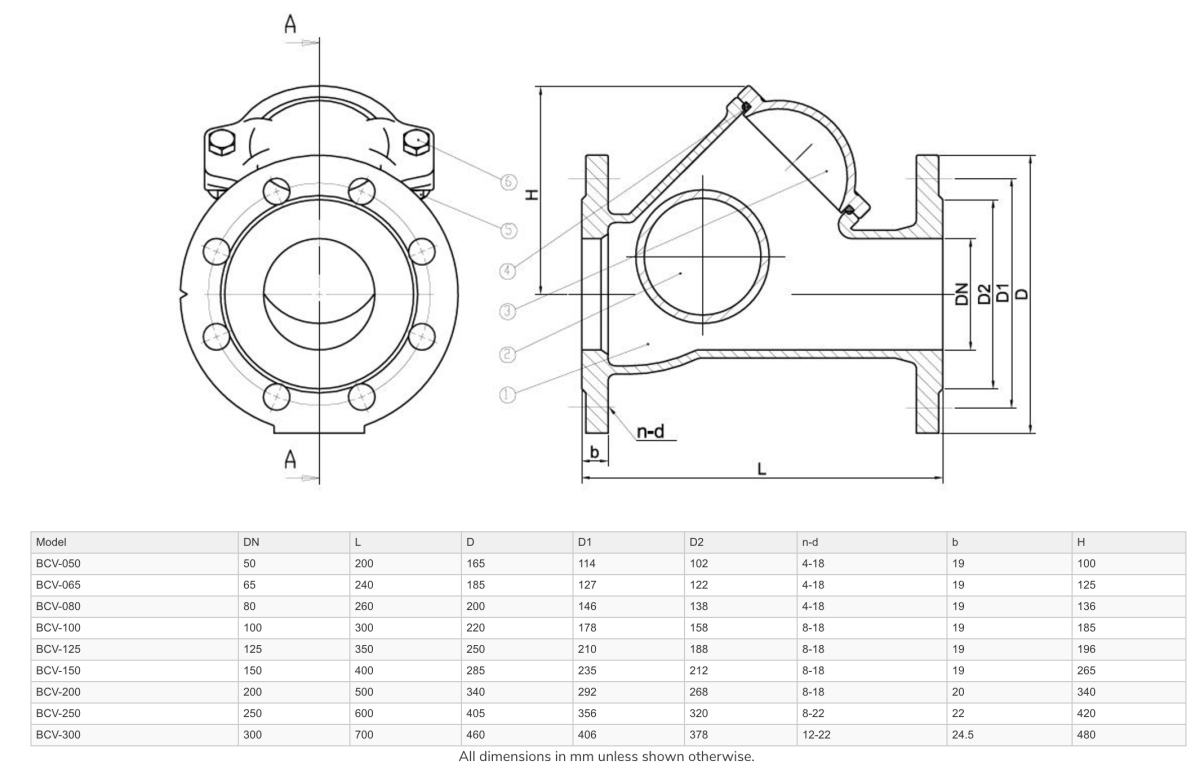

Fusion Bonded Epoxy coated Ductile Iron Ball Check Valve flanged to AS4087 PN16 / AS2129 Table E. Stainless Steel fasteners and NBR coated steel ball. Self Cleaning check valve ideal for applications where debris is present such as pump stations and sewerage which prevents other check valves been used.

Specifications

| Model | DN (mm) | Media Pressure | Media Temperature |

|---|---|---|---|

| BCV-050 | 50 | 0 to 16 BAR | 0 to 80°C |

| BCV-065 | 65 | 0 to 16 BAR | 0 to 80°C |

| BCV-080 | 80 | 0 to 16 BAR | 0 to 80°C |

| BCV-100 | 100 | 0 to 16 BAR | 0 to 80°C |

| BCV-125 | 125 | 0 to 16 BAR | 0 to 80°C |

| BCV-150 | 150 | 0 to 16 BAR | 0 to 80°C |

| BCV-200 | 200 | 0 to 16 BAR | 0 to 80°C |

| BCV-250 | 250 | 0 to 16 BAR | 0 to 80°C |

| BCV-300 | 300 | 0 to 16 BAR | 0 to 80°C |

Recently Viewed Products

- Choosing a selection results in a full page refresh.

- Opens in a new window.